Fette Compacting Collaborative Training in VR

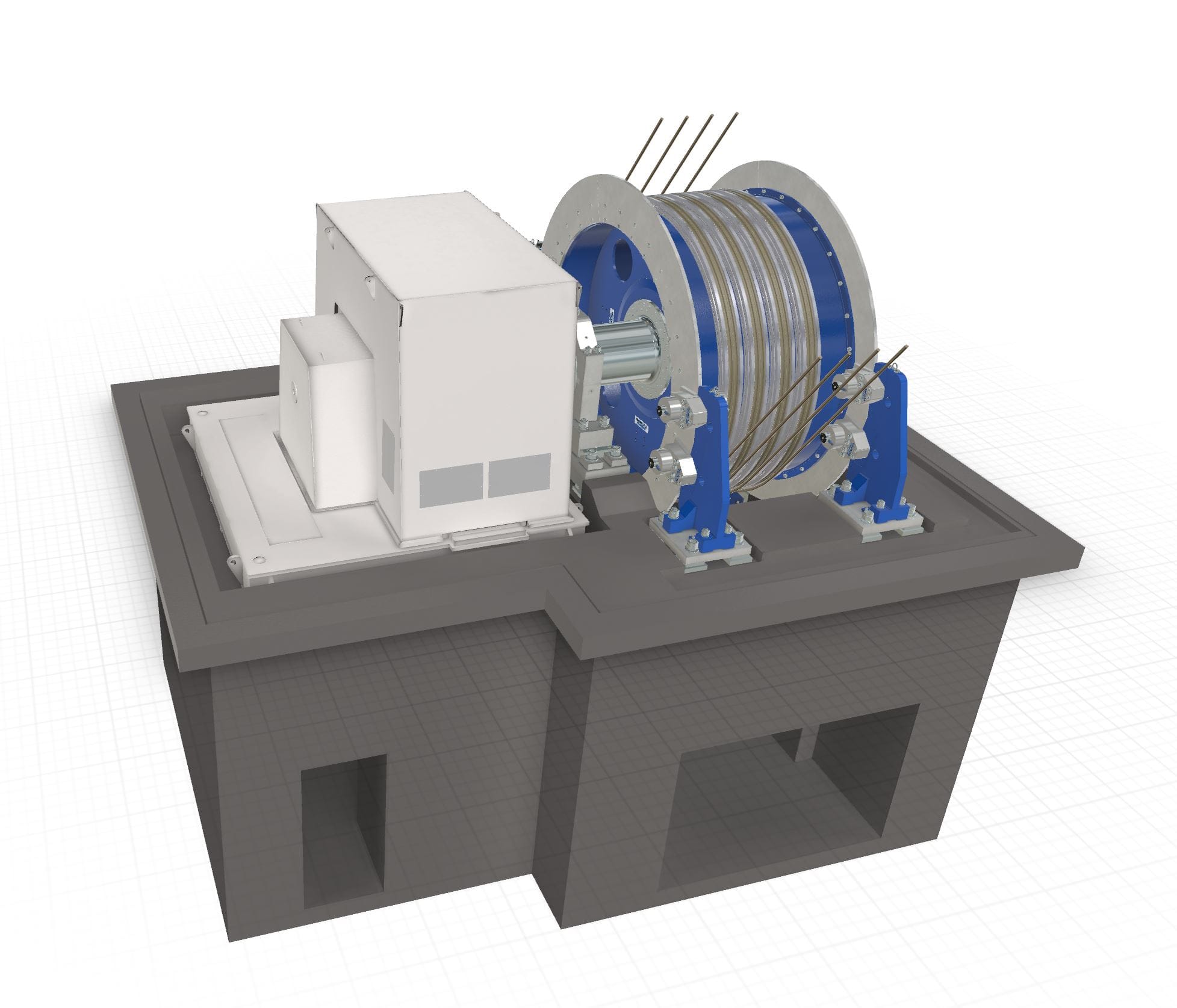

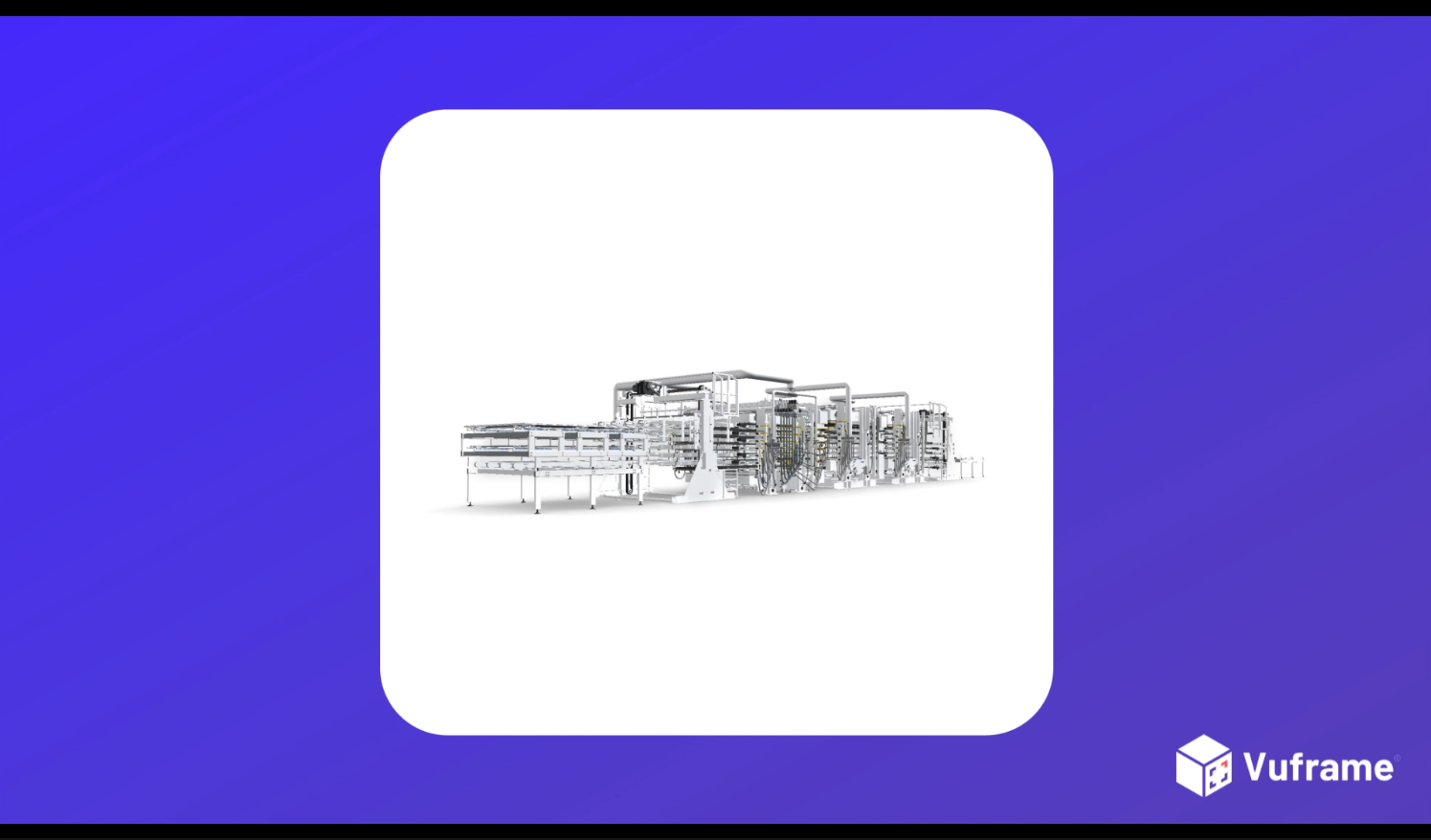

Fette Compacting uses virtual reality for collaborative training — allowing teams to explore machines together, practice workflows, and build knowledge in a safe, immersive environment.

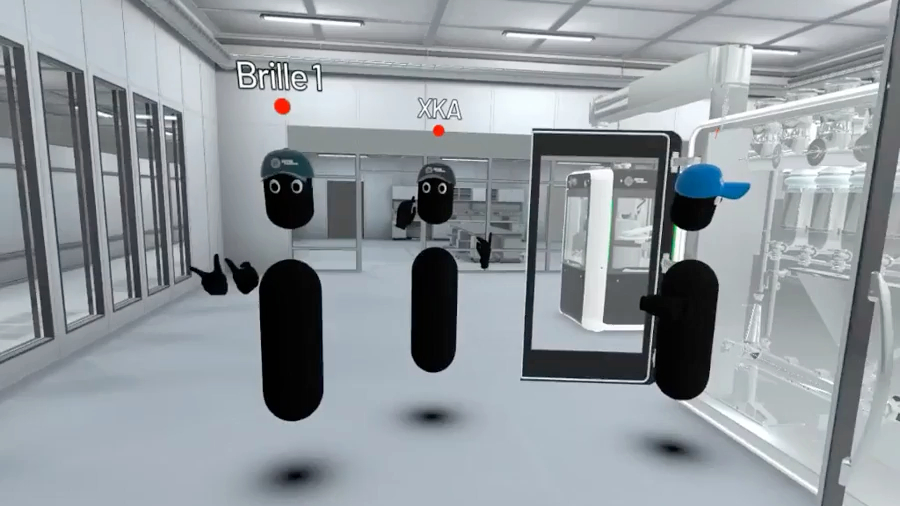

Walktrough: Single-Player Showroom & Multiplayer Laboratory

Multi-User Virtual Reality Training for Team-Based Excellence

Pharmaceutical manufacturing isn't a solo endeavor—it requires coordinated teams working in perfect synchronization. Fette Compacting's Collaborative Training in VR breaks down the isolation barrier of traditional VR learning, enabling multiple operators, technicians, and supervisors to train together in shared virtual spaces, regardless of their physical locations.

This multi-user VR platform creates digital training rooms where teams can simultaneously explore tablet press machinery, practice changeover procedures, and coordinate maintenance workflows. Participants appear as avatars within the virtual environment, complete with spatial voice chat that allows natural communication as if standing side-by-side at an actual machine.

Learning Together, Growing Together:

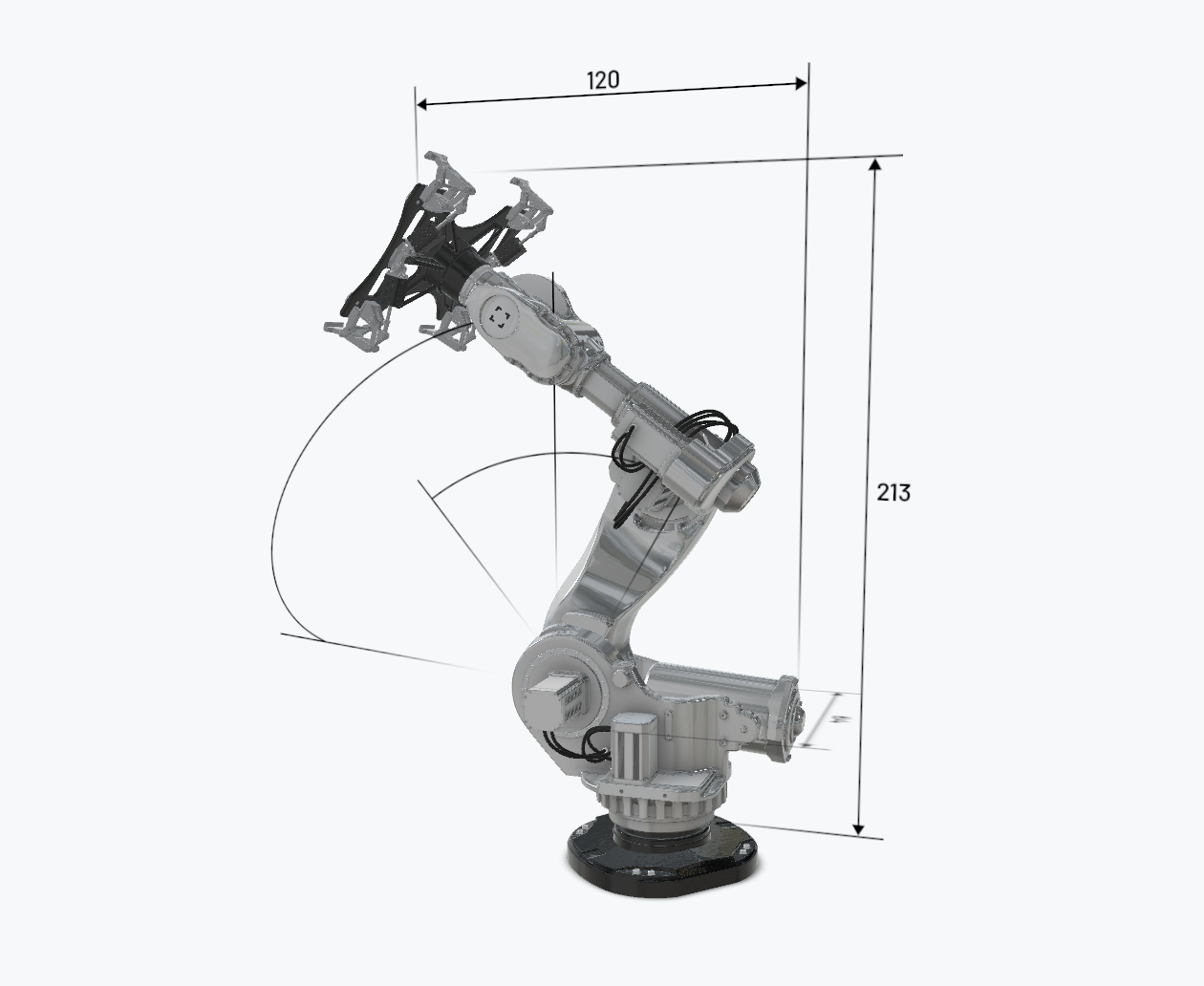

The collaborative dimension transforms training from individual skill-building into team synchronization. Operators practice coordinated changeovers where timing and communication are critical—one team member handles turret disassembly while another prepares tooling, exactly as they would on the production floor. Supervisors can join sessions to observe, provide real-time coaching, and demonstrate best practices to entire groups simultaneously.

Global teams benefit immensely from this technology. A maintenance expert in Germany can guide technicians in Brazil through complex troubleshooting procedures, pointing at specific components and demonstrating techniques within the shared VR space. Knowledge transfer becomes immediate and experiential rather than theoretical.

The platform records collaborative sessions for review, capturing team communication patterns, coordination efficiency, and individual contributions—providing insights that improve both technical skills and teamwork dynamics.